- So,

back to the black art of friction materials. While a "coefficient

of friction" number is a nice data point to consider when

modifying a braking system, what is even more important is the

ability of the material to maintain that coefficient under a

variety of driving conditions.

Brake pads with radical

changes in coefficient over their operating range are not a racer's

best friend. Be sure to select one that remains relatively stable

under the operating conditions you are expecting, but don't expect

any shorter stopping distances, because the brake pads don't

stop the car!

-

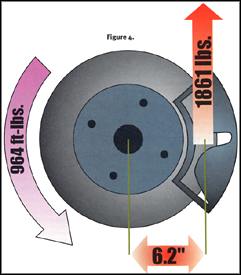

- The Rotor

- The

rotor actually stops the car--just kidding. Like the other parts

of the system mentioned so far, the rotor (Figure 4, above) does

not stop the car; however, unlike the other braking system, components,

the rotor serves two purposes, listed here in order of appearance:

The rotor acts as the

frictional interface for the brake pads. But because it is a

spinning object, it reacts to the output force by absorbing the

torque created. (Any time a Force is applied to a spinning object,

a torque is generated.) In this case, if we assume the force

to act at a point midway across the rotor face (6.2 inches from

the center of rotation in our example) then the torque is equal

to about 964 ft.-lbs.

- (1861 pounds x 6.2 inches / 12 inches

per foot).

The rotor must also

absorb the heat generated by the rubbing of the brake pads against

the rotor face.

In the case of the

second item above, the rotor dissipates the heat generated by

warming the air surrounding the rotor. This is why brake cooling

ducts are so useful. Where does the torque go? The 964 ft.-lbs.

sure is a lot of torque, and it has to go somewhere. (But, before

YOU go any further, you might want to check out the

sidebar, "Those Poor Rotors").

-

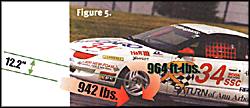

- The Wheels and Tires

- Time

to get down to business--and time to stop the car. Because the

wheel and tire are mechanically bolted to the rotor, the torque

is transferred through the whole assembly: rotor, hub, wheel

and tire. And now, the moment we have all been waiting for: It

is the interface between the tire and the road that reacts to

this torque, generating a force between the tire and the road

that will oppose the motion of the vehicle.

|

- The math looks just like the equation

to calculate the torque in the rotor, but in reverse. (See Figure

5, below.) Crunching the numbers based on a 275/35R17 tire with

a rolling radius of 12.2 inches shows that a force of 942 pounds

is generated between the tire and road, opposing the motion of

the vehicle

-

Ladies and gentlemen,

this is what stops the car--not the brake pads, not the rotors,

not the cool stainless steel brake lines. It's the road reacting

against the tire.

Now, in order to finish

the job, all that is necessary is to add up all the forces (remember,

there is a force acting on every wheel with a brake) and run

through a little more math. In case you haven't noticed, we engineers just

love this math stuff.

-

- Adding the Forces

- As

that famous guy Newton said,

- force = mass x acceleration (F=MA). Or,

stated another way, the acceleration (or deceleration as the

case may be) of an object will be equal to the sum of all of

the forces acting on the object divided by the weight of the

object.

-

- Before

we can sum up all the forces, there is one last little important

fact to consider: The tire forces are not the same for the four

corners of the car. Due to the static weight distribution of

the car, the location of the center of gravity of the car, and

the effects of dynamic weight transfer under braking (just to

name a few), the rear brakes are designed to generate much smaller

forces than the forces generated by the front brakes. For the

sake of argument, and for this exercise, we'll say the split

is 80 percent front and 20 percent rear, but the actual distribution

is dependent on the specific vehicle configuration.

- So,

if each front tire generates 942 pounds of force, then we can

calculate that each rear tire generates 20 percent of that, or

188 pounds. Adding up the four corners now gives us a total of

2260 pounds of force acting on the vehicle between the four tires

and the road.

-

- Rearranging

Newton's home run mentioned above, (decel = force / weight), we

can calculate that the total deceleration of the vehicle is 0.84g,

or 2260 pounds force / 2640 pounds weight. Easy, right?

|